The heat treatment of unhardened steel is called annealing. Some types of annealing are closely related and often combined

into one process. This integration is more likely to save time than to create an improved grain structure. Only the most relevant

annealing methods are listed below. Annealing steel has developed into a complex subject; precise process control, made possible by

sophisticated technical equipment, is often required. This ensures on an industrial scale constant results with time and energy efficient

processes, particularly required with higher alloyed steels.

A coarse lamellar or globular grain texture is achieved by soft annealing, making the steel soft and particularly well suited for machining with cutting tools. Stresses from rolling or forging are significantly reduced.

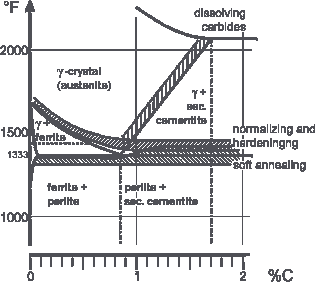

Soft annealing is done by heating to or commuting around Ac1. After holding at this temperature for a sufficiently long

time, slow cooling to about 1200°F completes the process. Below 1200°F faster cooling can be done since the transformation based on carbon migration already took place at higher temperatures. A sufficiently slow cooling can be done in the oven or by placing the specimen in ashes, a good insulation.

While holding the steel just below Ac1, carbon diffusion and surface tension of the cementite cause at first the formation of coarse lamellae thereafter of globular cementite. Globular cementites are spherical cementite segregations within ferritic grains, forming the so-called globular grain structure.

This globular grain structure is characterized by good workability. The carbides do not have to be split during cutting action, as is the case with perlite, hence increasing the service life of the tools used. When hardening, the globular cementite dissolves faster than lamellar

cementite, requiring a shorter time above A3 to carbon-saturate the austenite by dissolving the carbides. This shorter

holding time reduces the grain growth during hardening.

Internal stresses are reduced without altering the microstructure by heating to about 1200°F and slow cooling thereafter. In contrast to soft

annealing this process has little to no influence on the carbides, hence preserving the grain structure and hardness. The stress relief heat treatment is not suited for bainitic or martensitic microstructures.

Normalizing is a "gentle" hardening, refining the grain by a fast gamma-alpha transformation, resulting in

a fine and even (normalized) microstructure. Bands of segregations are often removed. When normalizing, steel

is shortly heated to 50° to 90°F above Ac3 and then fast cooled but not quenched, like while hardening. Longer holding times than required for heating the steel are neither necessary nor advisable.

Hypereutectoidic steels (above 0.83%C) are normalized from above Ac1.

Instead of normalizing from Ac1, hypereutectoidic steels can also be normalized from above Acm. In this case the annealing to dissolve the secondary cementite (grain boundary cementite) is combined with the above mentioned soft hardening. Once the cementite-shells between the grains are dissolved, the risk of undesired grain growth is increased. Mechanical deformation while fast cooling from Arm to Ar1 is therefore advisable. This process is used to produce superplastic steel, requiring close process control.

The often-applied sequence of multiple normalization cycles should only be used in case of extreme grain-growth, resulting

from over-heating the steel while forging or forge-welding. The second cycle of normalizing will not alter the grain-structure of correctly worked steel.

The heat treatment required for hardening is discussed more detailed in the section grain-structures. Bainitic-hardening is more

frequently used among American smiths and suited for blades exposed to high mechanical load.

Prior to hardening, steel should have a fine globular grain structure. The heat treatments required for such a microstructure are first

normalizing and thereafter soft-annealing. Normalizing can be done in combination with the last forging heat or by an individual cycle.

Annealing to globular cementite is only required with hypereutectoidic steel. The remaining grain boundary cementite prevents grain growth while soft-annealing.

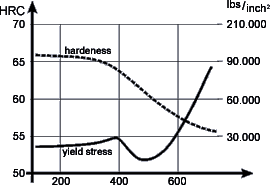

Tempering is essential after martensitic hardening. This process transfers the tetragonal martensit into the tougher cubic

martensit. Hypereutectoidic steels can show an increase of hardness caused by segregations, the so-called secondary hardening.

Tempering decreases the internal macroscopic tensions, easing remaining austenite to transform to martensite. Multiple tempering cycles are required to temper this newly developed tetragonal martensit. The cubic martensite is tougher but slightly less hard than the tetragonal martensite. A mechanically loaded blade of tetragonal martensite will break or chip when in use. When tempering in the range of 500° to 600°F the so-called tempering brittleness occurs. Tempering to this temperature range will result in a loss of of ductility and hardeness. A bluish oxidation color characterizes this condition, therefore it is also

called blue-brittleness.

When tempering in the range of 500° to 600°F the so-called tempering brittleness occurs. Tempering to this temperature range will result in a loss of of ductility and hardeness. A bluish oxidation color characterizes this condition, therefore it is also

called blue-brittleness.

© 2005 G.v.Tardy